We Do

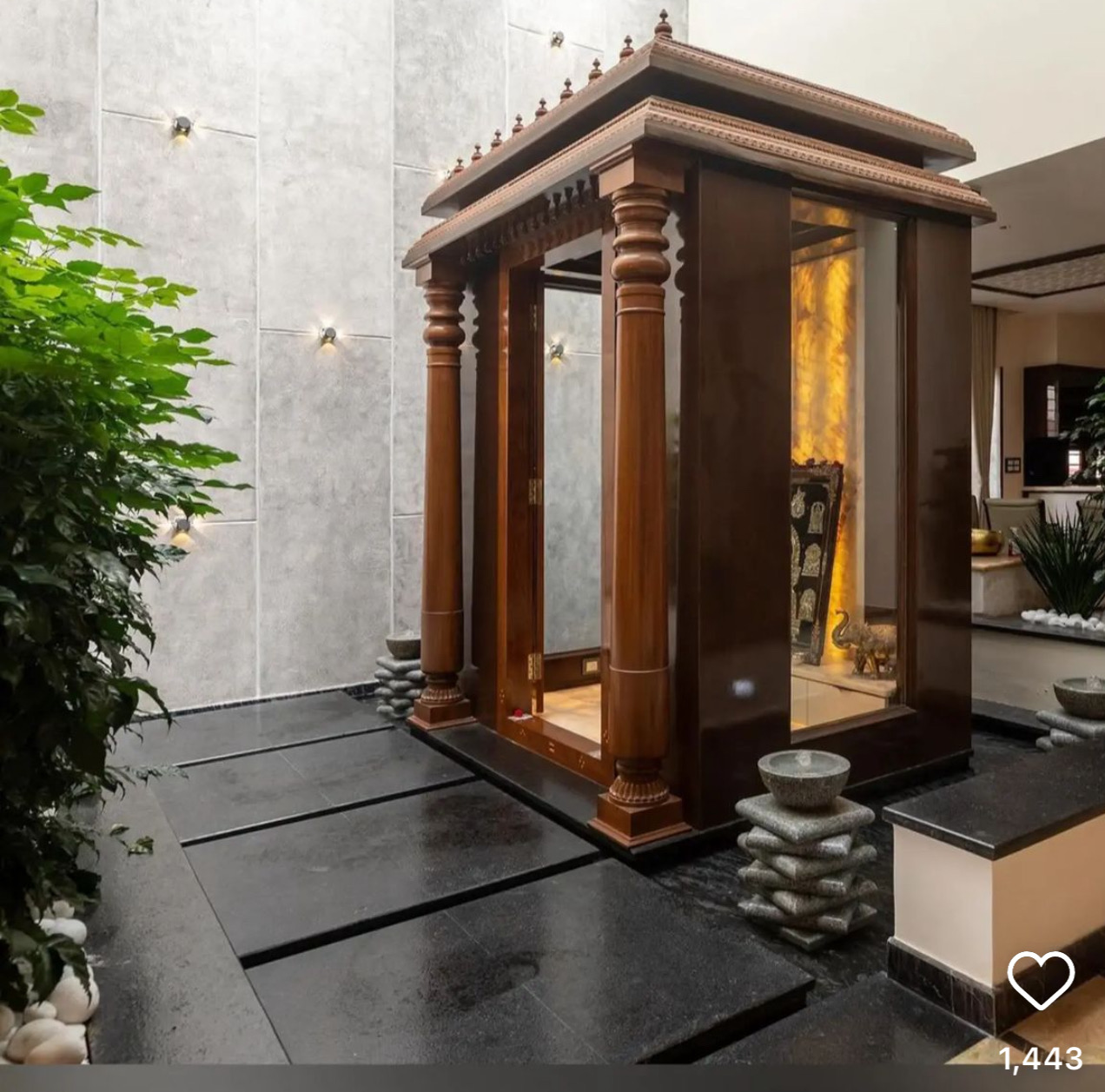

Bless One Construction Group specializes in building all kinds of villas, ,Dedicated ARCHITECT service under the name - Bless One Architects,Dedicated INTERIOR FIT-OUT service under the name - Bless One Interiors.,Dedicated WOOD WORK service under the name Bless One wood works ,Dedicated FURNITURE service under the name Bless One Furniture .

Work

M-Sand Process and Advantages

The process consists of 3 stages

- a) Crushing: Hard stones are crushed in Vertical Shaft Impact crusher where cubical and angular fine aggregate particles are produced.

- b) Screening: The process of screening helps in the proper grading of the material to make it similar to river sand.

- c) Washing: The microfine particles are removed by washing. This M-Sand is vastly different from that of crusher dust. Additionally, in the washing process, both fine aggregates for concrete and plaster sand can be generated.

Advantages of M-Sand

- a) Consistent Supply: M-Sand can be produced in areas closer to construction sites, bringing down the cost of transportation and providing an assurance of consistent supply.

- b) Lesser impurities and good working properties’ Msand and is free of silt and clay particles, and has denser particle packing than natural sand.

- c) Excellent Strength: Compared to river sand, M-Sand has a higher compressive strength, higher flexural strength, better damage resistance, better water retentivity, higher unit weight, and lower permeability as well.

- d) Better work-ability: The cubical shape with a rounded edge and superior gradation of M-Sand gives good plasticity to mortar, providing excellent workability.

- e) Eco-friendly alternative: Usage of M-Sand prevents dredging of river beds to get river sand which may lead to environmental disaster like groundwater depletion, water scarcity, a threat to the safety of bridges, dams etc. M-Sands is an Eco-friendly alternative to river sand.

- f) Economy: Since the usage of M-Sand has increased durability, workability, higher strength, d