We Do

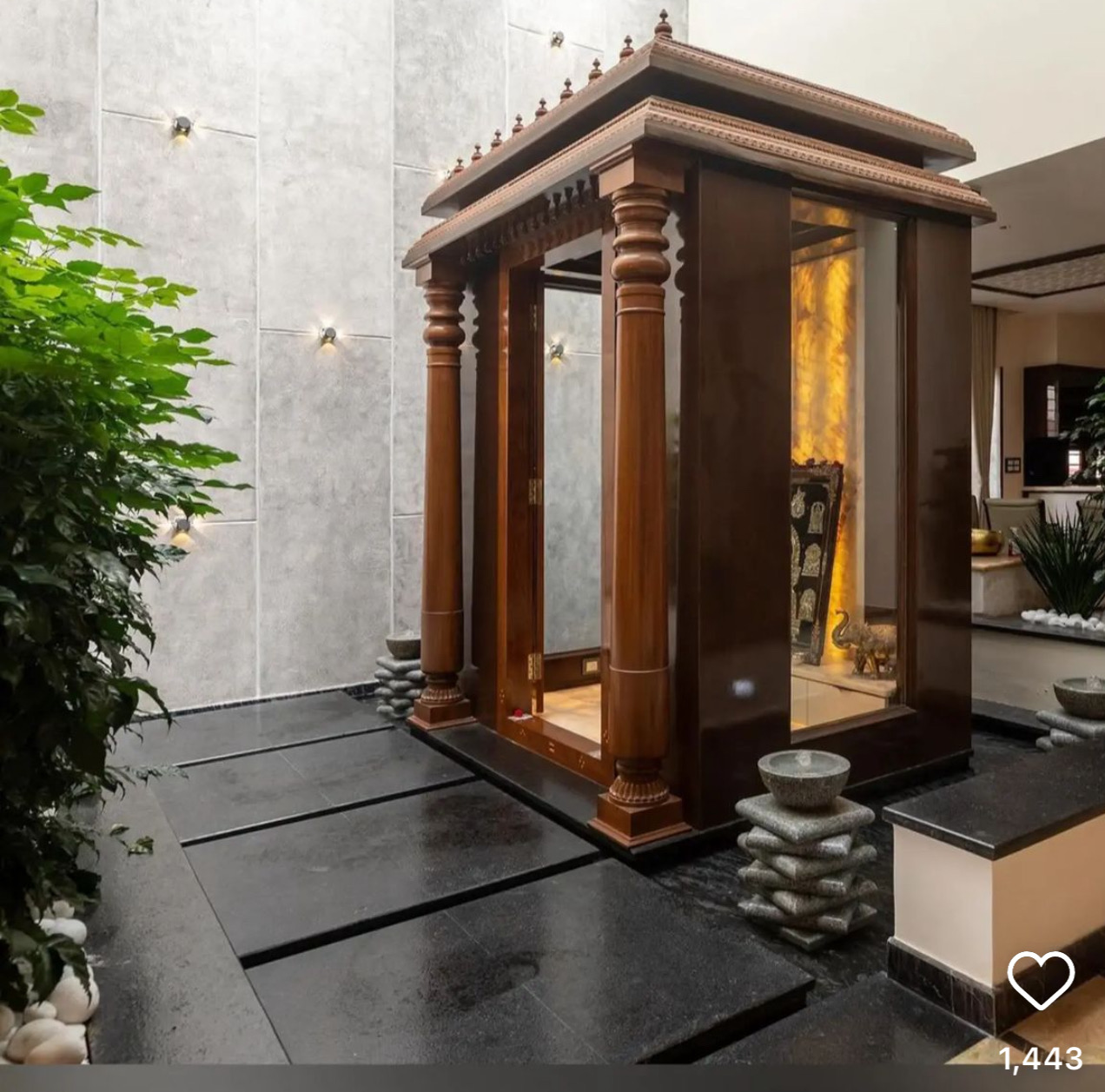

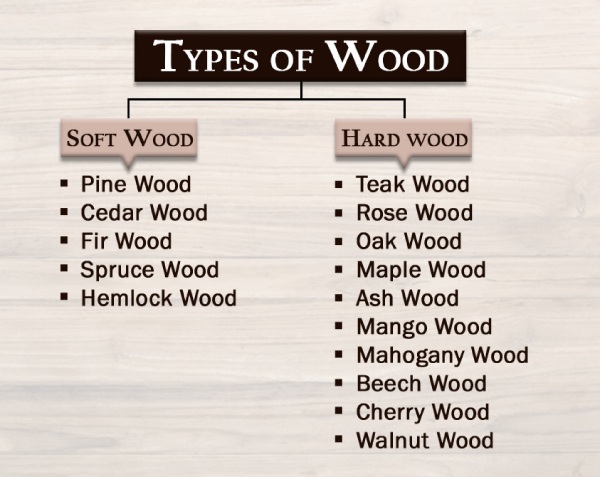

Bless One Construction Group specializes in building all kinds of villas, ,Dedicated ARCHITECT service under the name - Bless One Architects,Dedicated INTERIOR FIT-OUT service under the name - Bless One Interiors.,Dedicated WOOD WORK service under the name Bless One wood works ,Dedicated FURNITURE service under the name Bless One Furniture .

Work

Construction Quality Management: Make a Great Plan & Stick to It

What is quality planning in project management?

In construction, “quality” entails a project meeting its design requirements. When quality is ignored, the ensuing troubles may range from cosmetic defects to structural failures, and everything in between. These, in turn, are likely to cause rifts among the project’s stakeholders.

This is why quality is one of the 3 tenets of construction, along with time and budget.

Typically, the General Contractor’s (GC) site superintendent makes sure that the work is finished per the stated quality standards. This conventional approach lacks efficiency, as many contractors don’t have defined quality management programs. To this end, owners may benefit from a quality plan built into the overall project plan.

This post will examine benefits of quality planning, the key elements of a construction quality plan, and its implementation.

How do I write a construction quality plan?

1. Establish the client’s quality expectations

Most owners expect a certain level of quality from their projects. They convey these expectations to the design team before the latter gets to work.

For a PM drafting their quality plan, it’s equally vital to know what level of quality the owner desires. They may want to formalize a quality control procedure in the specifications. Or, they may let the PM take the lead on quality. Either way, the PM must understand the client’s quality benchmark and write the plan with it in mind.

2. Designate quality management personnel

A quality manager shoulders the weight of the overall project quality, while